WORKSTATION DESCRIPTION

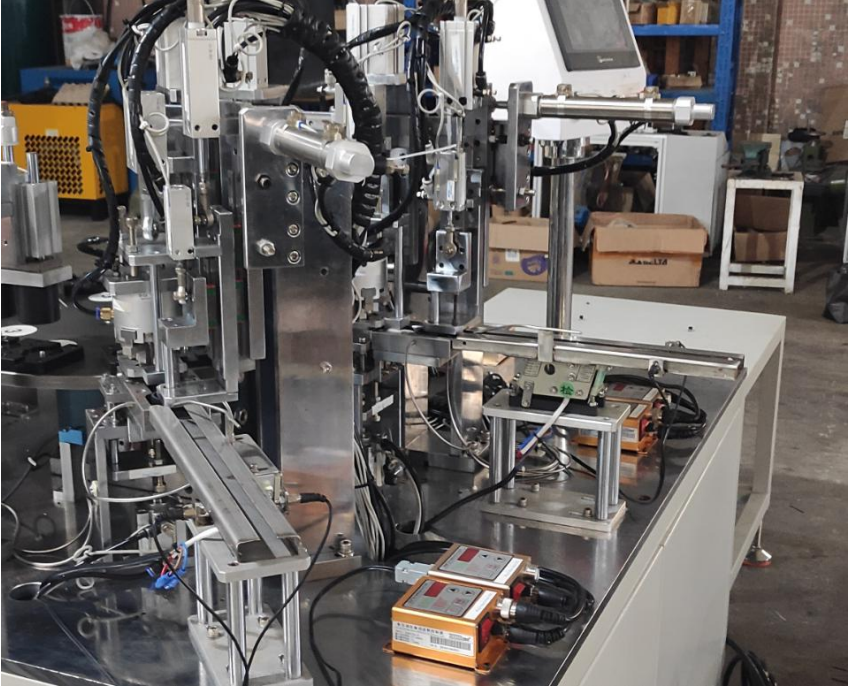

POM workstation

This workstation consists of POM refilling hopper, aims to provide an roller refill in time into vibration feeder bowl in case of machine shutdown because of run-out of roller in vibration feeder bowl.

Roller hopper is driven by its bottom linear vibration feeder works with detection mechanism that mounted onto roller vibration feeder bowl to provide automatic feeding signal to feeding hopper.

POM roller vibration feeder bowl aims to provide automatic orientating, sequencing, transferring

POM roller to feeding track driven by linear vibration driver. Feeding track is introduced to transfer orientated and sequenced rollers from vibration feeder bowl to separate mechanism.

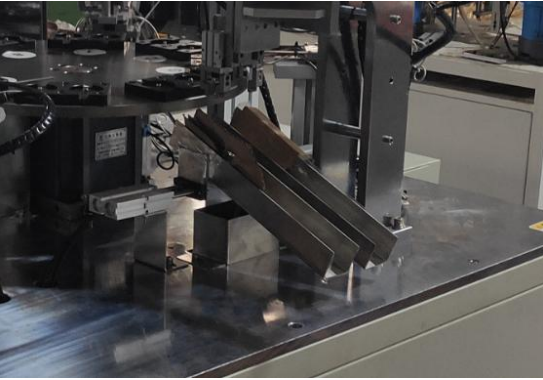

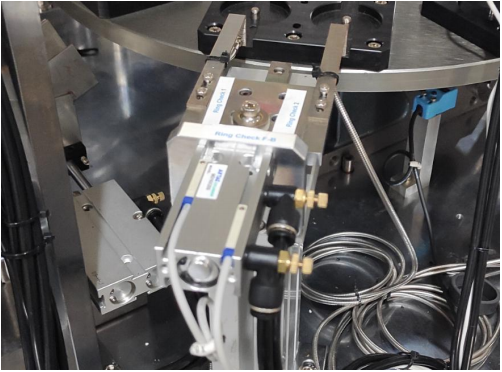

POM Roller Separate Mechanism

In POM roller separate mechanism, there is a fiber sensor at the end of POM roller feeding to detect if POM roller enter into separate mechanism in right position. Separate driven pneumatic cylinder works to separate 2 rollers into left and right ends. Left forward and left push mechanism works to push one roller into left centering mechanism and await for roller pick-place gripper. Right forward and right push mechanism works to push another roller into right centering mechanism and await for roller pick-place gripper.

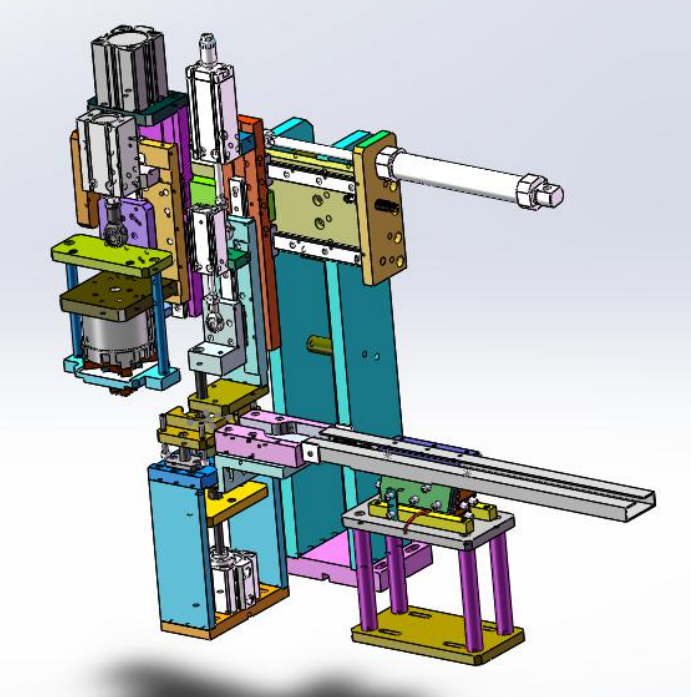

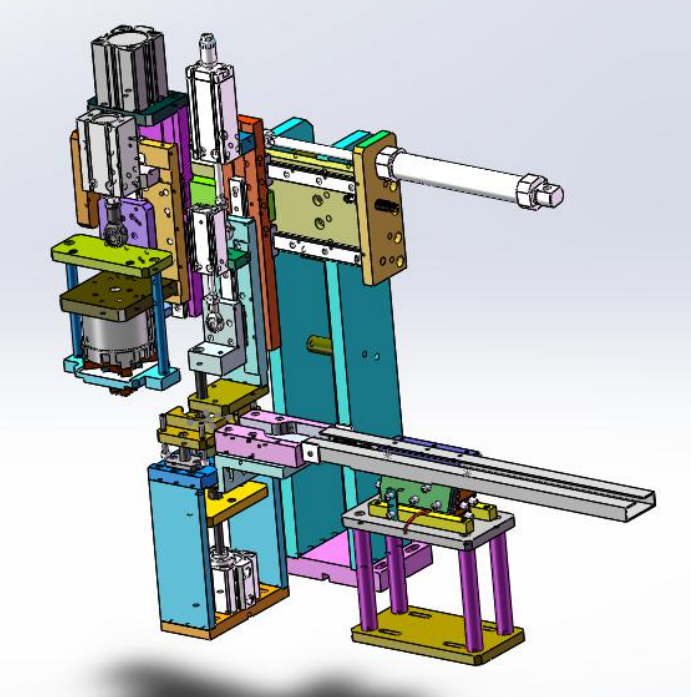

POM Pick-Place

When 2 rollers enter into left and right centering mechanisms, pick-place grippers descend to pick 2 rollers at the same time, then rise up, move forward, descend to place 2 rollers into fixtures onto indexing table and then pick gripper rise up and move backward to origin position.

POM Detection

2 piece of fiber sensors that mounted at the POM detection workstation to detect if 2 rollers are placed into the fixtures of rotary indexing table. If POM can not be detected, continuous process such as rubber ring assemble will be canceled.

Rubber Ring Workstation 1 & 2

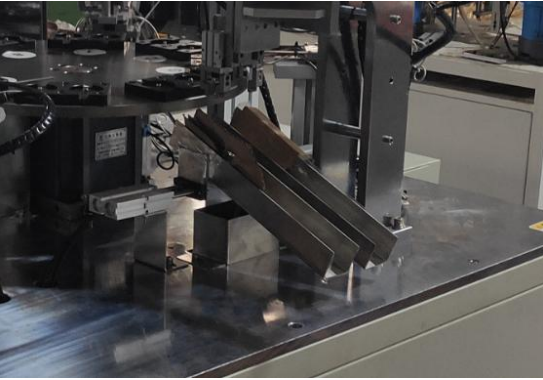

Rubber Ring Load & Feed

This workstation consists of rubber ring vibration feeder bowl and feeding track driven by bottom linear vibration feeder. Vibration feeder bowl aims to orientate, sequence and transfer rubber ring to feeding track. Feeding track driven by bottom linear vibration feeder to transport rubber rings come from vibration feeder bowl till to the end of separate mechanism.

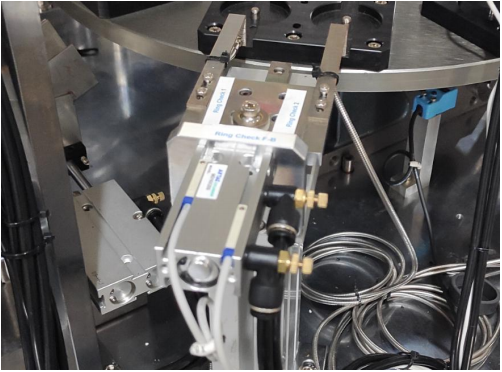

Rubber Ring Separate

Rubber rings that transferred by feeding track enter into the end of separate mechanism. A fiber sensor mounted onto separate mechanism detect that if the rubber enter into separate mechanism. Once rubber ring detected, the rubber ring drag rod and press-plate move down one by one and move forward to drag the rubber ring into rubber centering mechanism and the rubber ring press-to-drag mechanism return and wait for drag another rubber ring to centering mechanism.

Rubber ring that dragged into rubber ring centering mechanism, 4 pins to shape the rubber ring to ensure that the rubber ring gripper can enter into the internal side of rubber ring. 4-claw gripper move down, rubber ring ejection mechanism ejects, 4-claw gripper open to pick up rubber ring. Entire mechanism rise up to a place that above fixture onto indexing table and align with roller onto rotary indexing table. Entire mechanism descend, rubber press mechanism works to press rubber ring to assemble with roller. After assembly, entire mechanism rise up and 4-claw gripper close, entire mechanism move backward, thus to complete one movement cycle for rubber ring assemble with roller.

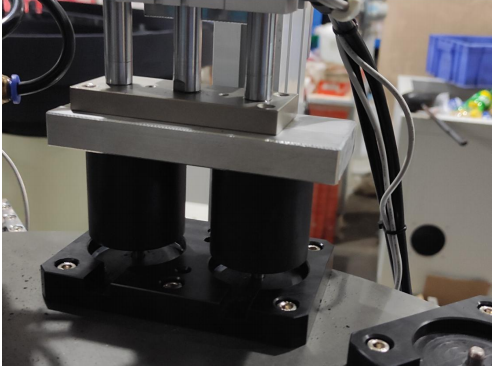

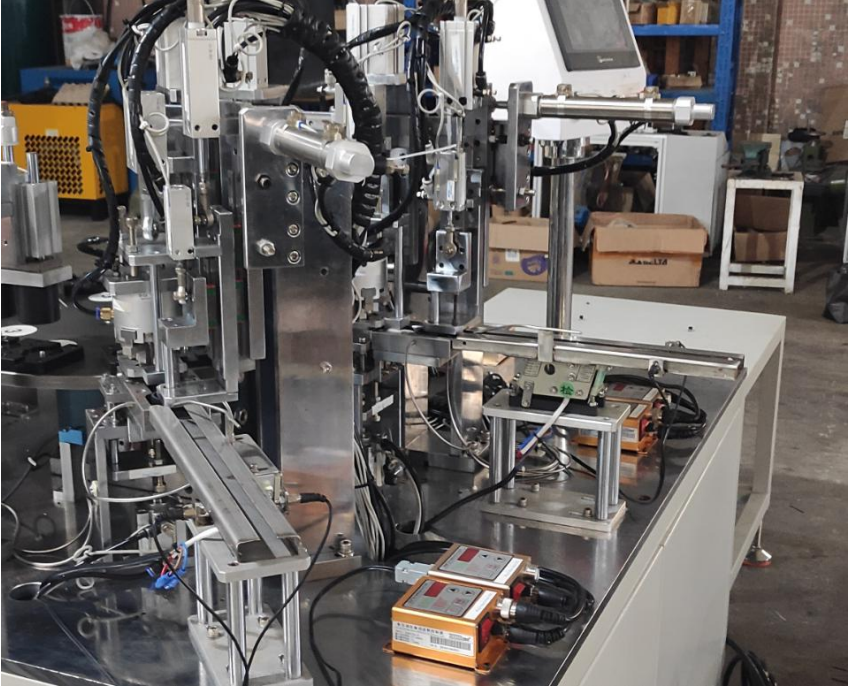

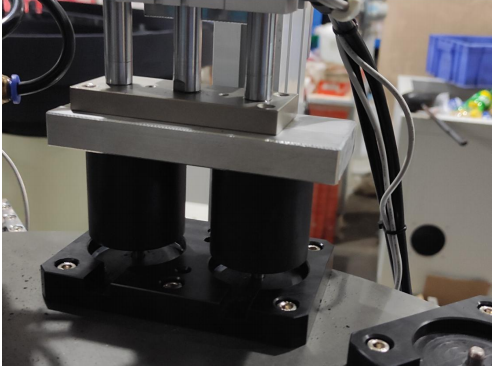

Rubber Press-To-Flat

This work station aims to press the rubber rings after rubber rings assembled with rollers in case of that rubber rings were not assembled well with rollers by previous two rubber ring assembly workstations.

Rubber Ring Detection

Two fiber sensors to detect the assembled POM rollers if any rubber ring missing. If the sensor fail to detect the rubber ring onto POM roller, the product will be determined as NG product.

Final Unloading & NG Sort

Final unloading & NG sort aims to separate and unload final products into final OK product track and final NG product track in accordance with the signal from fiber sensor detection from previous sensors.