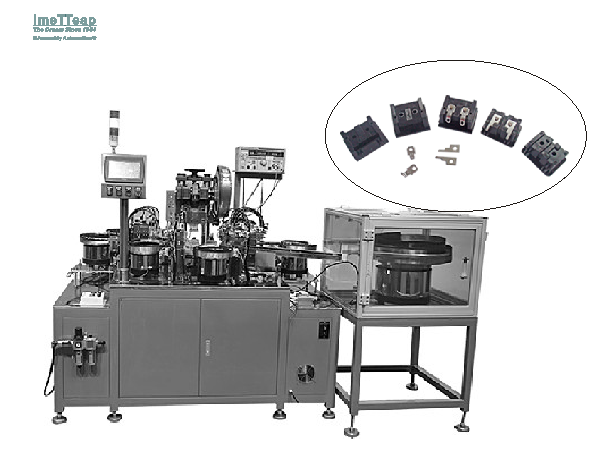

Power Jack Assembly Machine

Power Jack Assembly Machine

GENERAL INTRODUCTION-Power Jack Assembly Machine

Power jack assembly machine with full non-standard design based on analysis of parts and components that provided by user, help the user to achieve an

automated power jack high-speed assembly and high-quality production demand to meet customer’s specification.

Standout systematic integration To Power Jack Assembly Machine

This power jack assembly machine with full-custom design and engineering provides excellent parts loading and feeding system to resolve and replace manual

feeding ideas in the past.

Vibratory feeder bowl in different size are designed and developed based on feeding verification to load and feed different parts such as plastic housing of power

jack as well as terminal, springs and riveting nails with automatic loading, moveing direction orienting, parts sequencing and conveying.

The assembly workstation is introduced with rotary indexing conception to pick and place the plastic parts and metal parts into special processed fixtures to

position and assemble the product in accordance with assembly flow specification.

Pneumatic Driven pick-and-place mechanism places an important role for this power jack assembly machine to pick plastic/metal parts from parts feeding track to

assembly working station that mounted on an rotary indexer. The assembly proceses will be done one step by one step to assembly the product from semi-finished

assembly to final assembly.

To answer for customer’s special requirement,in-line hi-pot test system is introduced for this power jack assembly machine to test and inspect final product

continuously with production implementation. And other NG-OK sorting mechanism is designed beside of test system to sort NG product from OK products.

FUNCTION FEATURES-Power Jack Assembly Machine

Vibratory Feeder Bowl To select, orientate, sequence and convey plastic parts and metal parts as an alternative solution for manual material loading;

Workstation layout in accordance with scientific design as rotary indexing table with fixtures mounted onto working platform, easy to observe and easy to

maintenance;

Integrate with assembly movements as well as in-coming inspection, checking and sorting to ensure the qualification of material in-coming and final product

cosmetic inspection and electrical properties test;

Designed with Mitsubishi PLC programmer as well as Wecon Touch panel as core control system to master entire assembly system, inspection system as well as

loading and unloading system, PLC and touch panel with other brands available for optional;

Brand pneumatic component such as air cylinders are introduced with famous brand such as FESTO, SMC, AirTAC etc to guarrantee automated power jack asssembly

machine working in stable and reliable performance.

OPTIONAL FUNCTIONS

Entire Shield To Protect Operator & ease noise from vibratory feeder bowl;

Electrical property testing projects: Hi-pot

Parts check in every single station available

CCD vision for cosmetic inspection such as terminal bending angle compliance, terminal flatness etc.

VIDEOS FOR REFERENCE