GENERAL INTRODUCTION

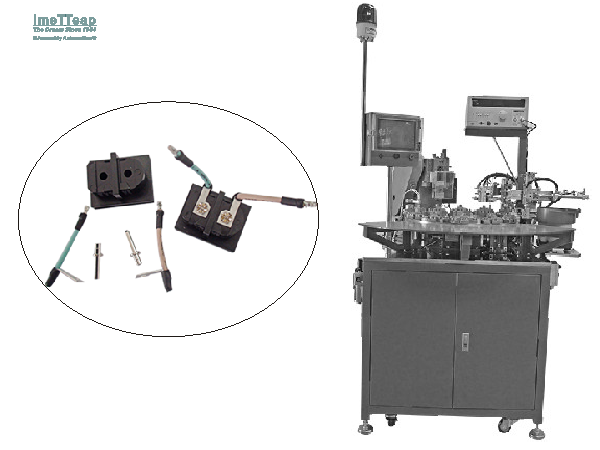

This AC power jack assembly machine in full-custom design and engineering, aims to help the manufacturer of AC power jack manufacturer to automate the

assembly process in production to achieve a high production rate as well as high quality final production.

AC Power jack series assembly machines have numerous applications in AC power jack manufacturing, but also find their way into various similar metal products

and plastic products.

A large number of industries place high demands on the applied assembly technologies, which is why production processes are still largely dominated by manual

assembly operation, impeding competitive production in high-wage areas and countries.

With advanced engineering and design concept, lmeTTeap and its strategical partners are developiing solutions for flexible, precision assembly automation solution

and automated assembly machines.

ASSEMBLY FLOW

Plastic Housing Loading, Feeding, Sequencing & Orientating;

Central Pin Loading, Feeding, Sequencing & Orientating

Central Pin Inserting Into Fixture

Central Pin Assemblied with Plastic Housing

Spring Plate Contact With Wire Manual Loading onto Fixtures

Automated Riveting & Assembly

Final Product Hi-Pot Test & Inspection

Final Inspection & NG-OK Sorting

Final Product Unloading

FUNCTIONAL FEATURES

Introduced with rotary indexer into the worksation to perform the assembly processes one step by one step from raw materials loading and feeding such as plastic

part as well as metal parts loading & feeding.

Special machining fixtures are mounted and installed onto the rotary indexer that drive by precise controlled motor with complete the assembly flow in accordance

with assembly demand and requirements from customers side.

Special-design and made vibratory feeder bowls to load, feed, select, sequence and orientate parts to be loaded and fed into next assembly or process station in

right direction and right position precisely;

The machine control system consists of mitsubishi PLC as well as Wecon color touch control panel to control the entire assembly system to guarrantee a stable and

reliable assembly performance;

TECHNICAL PARAMETERS

Overall Dimension: Approx. 750×550×1400mm

Gross Weight: 500KG

Air Pressure: ≥0.5Mpa

Power Supply: 220V, 50/60Hz

Production Rate: 20-40pcs/min. (determined by different raw material and assembly processes)

Operational Rate: ≥95%

Reject Rate: ≤1%