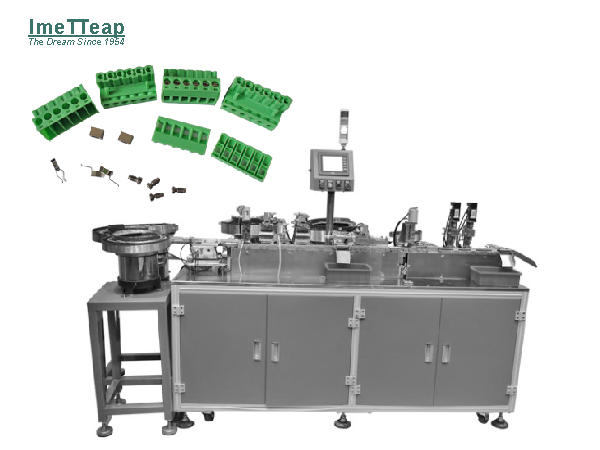

Terminal Blocks Assembly Equipment

GENERAL INTRODUCTION

This automated terminal block assembly machine is designed and made with aim to provide a full-automated

assembly performance for a variety of terminal block, wire terminal series products.

This terminal block assembly machine allows terminal block manufacturers to improve terminal block assembling

and production quality, increase the productivity and enables a highly automation level to save labor investment

and production cost in a terminal block production line.

Vibratory feeder bowls have been designed with the integral terminal block assembly machine. Thanks to full-custom designs for these vibratory feeder bowl to load, feed, sequence, and orientate the metal & plastic components

and parts.

Automatic assembly mechanisms that mostly drive pneumatic components will perform the assembly movements

such as insertion, pressing, screwing in an automatic way in a planed processing sequences.

Employs core control system that consists of PLC & touch control panel to control entire assembly system and

ensure the assembly sequence run according to the program that memoried in PLC, while the operational status can

be displayed in touch control panel.

PLC with full-custom developed software codes to control every single automatic movement actuator to fulfill

the single mechanism that consist of pneumatic drive components or motorized drive components;

PLC program can monitor and display the complete production process and production flow. PLC works with

alerting system (normally with tri-color light tower and buzzer to warn operator if any troubles for assembly machines)

for no material feeding (material empty) material getting stuck, or other troubles.

PLC program can perform an automatic statistic for production as per mininutes, hours, days, or monthly.