GENERAL INTRODUCTION

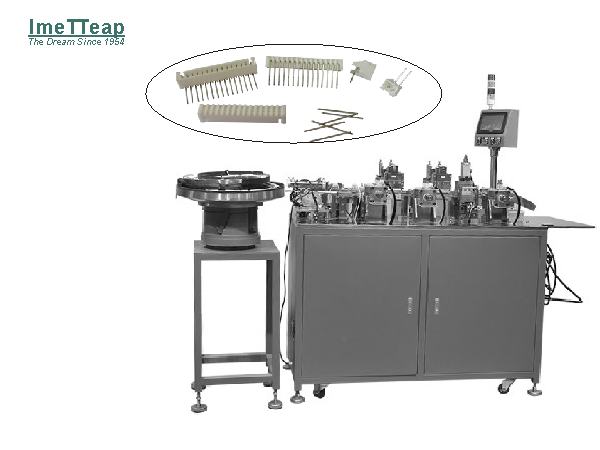

Wafer Connector Assembly Machine with advanced design concept is made with aims to provide an one-stop solution for assembly production for wafer connector.

Wafer connector assembly provides assembly automation as well as sub-systems that include parts and components loading system based on material analysis and

feasibility analysis and verification.

Vibratory feeder bowl, in full custom design and engineering, is available to load & feed plastic parts and pin in bulk, meanwhile, the vibratory feeder bowl can

sequence, orientate and feed them one by one with constant speed.

Special-purpose tracks to convey plastic housing as well as other special tracks to convey metal pins in ideal order.

Parts separating system to separate parts and components from conveying tracks into independent unit and ready to be processed or assemble with other parts.

Single Insertion Process Or row pin insertion can be achieved in accordance with different production rate demand; special cam drive mechanism will enable the

wafer connector assembly machine to achieve an high speed production rate up to 1200 pins/min.

ASSEMBLY FLOW

Pin In Bulk Loading (VFB)

Plastic Housing Loading (VFB)

Pin Insertion (Special Cam Drive Mechanism)

Final Product Inspection

Final Product Unloading

TECHNICAL SPECIFICATIONS

Machine Name: Wafer Connector Assembly Machine

Overall Dimension: 1500×750×1200 mm

Gross Weight: 350kg

Production Rate: 1200 pin/min.

Operational Rate: 90%-98%

Reject Rate: less than or equal to 1%

Power Source: 110-240V,50/60Hz

Power Source: 4kg/cm²