GENERAL INTRODUCTION

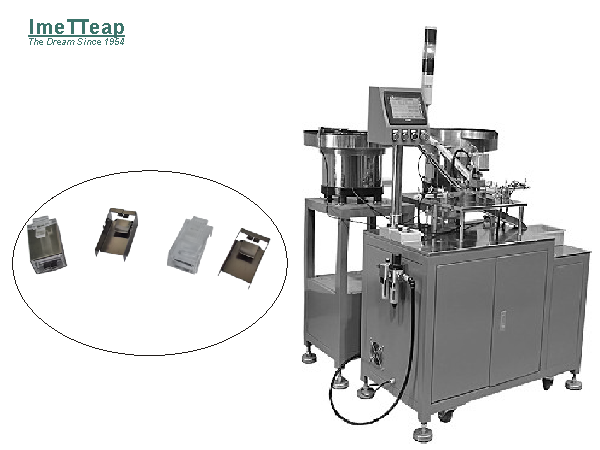

This automatic metal shield wrapping machine for Modular plug has been made in full custom aims to provide an one-stop assembly automation solution from

parts loading, feeding, seperating, inserting, riveting and rejecting to final unloading.

This automated metal shield wrapping machine for Modular plug (8P8C) allows the manufacturers of modular plug connectors to achieve an full automation

solution to reduce manpower input and improve the assembling quality for final products.

Driven by branded pneumatic components as well as special designed mechanism, this automated metal shiled wrapping machine can perform with stable and

reliable assembly production with production rate at 45-60pcs/min.

ASSEMBLY FLOW

Modular Plug Loading

Modular plugs in bulk are loaded and fed through a special design and made vibratory feeder bowl to load and feed modular plug with constant speed to answer

for assembly production rate;

Metal Shield Loading (VFB)/Coil Feeding

Metal Shield can be loaded and fed through two independent methods of vibratory feeder bowl and coil feeders to guarrantee a constant feeding speed;

Inserting & Assembling

Modular plug & metal shield will be seperated (or cut from strip of coil feeder) and modular plug will be inserted into metal shield one by one through special

purposed pushing mechanism after centering;

Riveting & Final Assembling

An Automatic Riveting Mechniasm to rivet metal ears between each sides of metal shield to fix the modular plug and metal shield, thus to complete the assemble

assembly;

TECHNICAL SPECIFICATION

Machine Name: Metal Shield Wrapping Machine For Modular Plug

Overall Dimension: 1500×750×780 mm

Gross Weight: 300kg

Production Rate: 50-60 pcs

Operational Rate: 90%-98%

Reject Rate: less than or equal to 1%

Power Source: 110-240V,50/60Hz

Power Source: 4kg/cm²