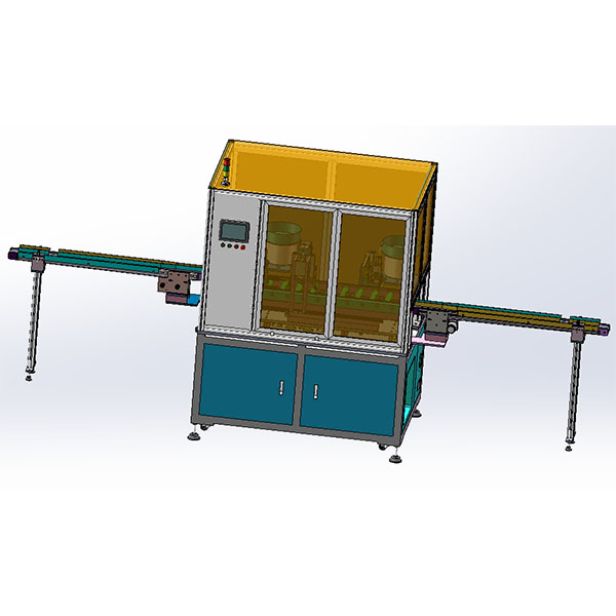

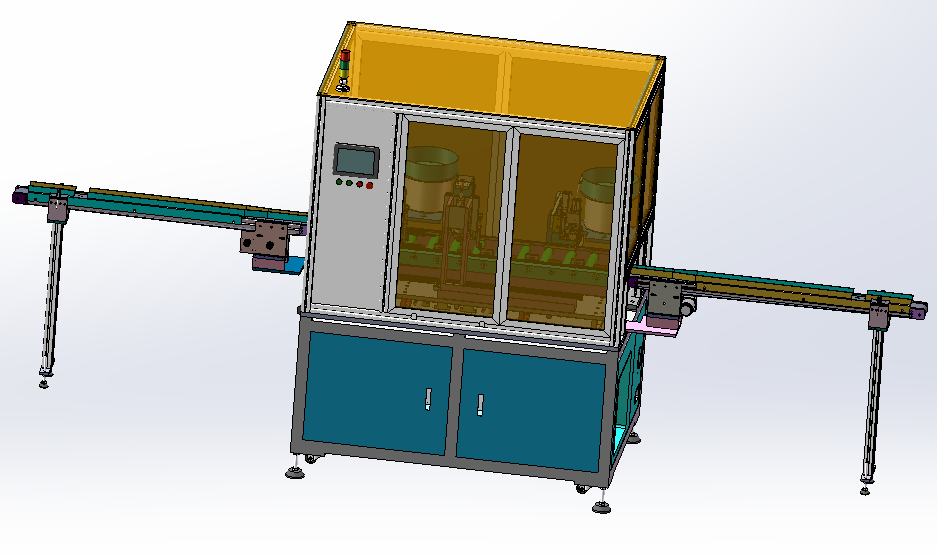

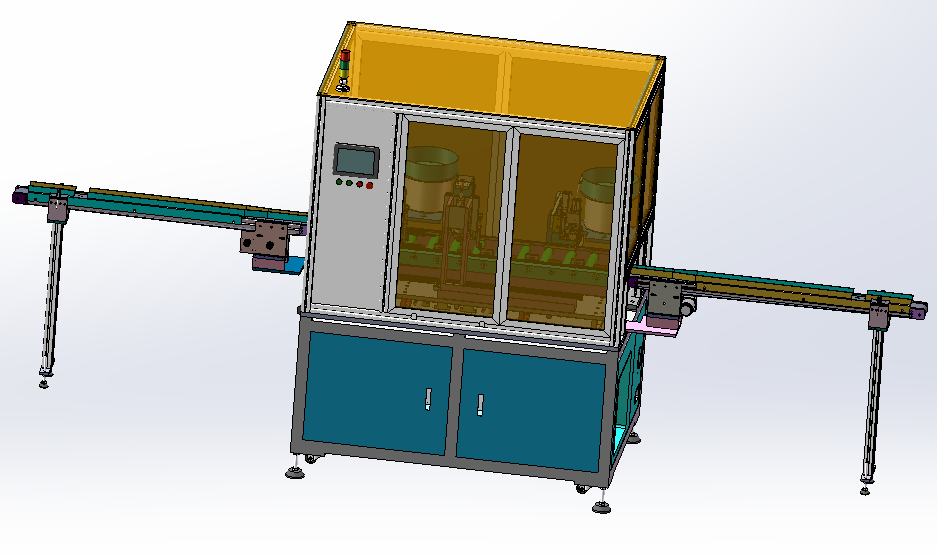

1. Machine Overview

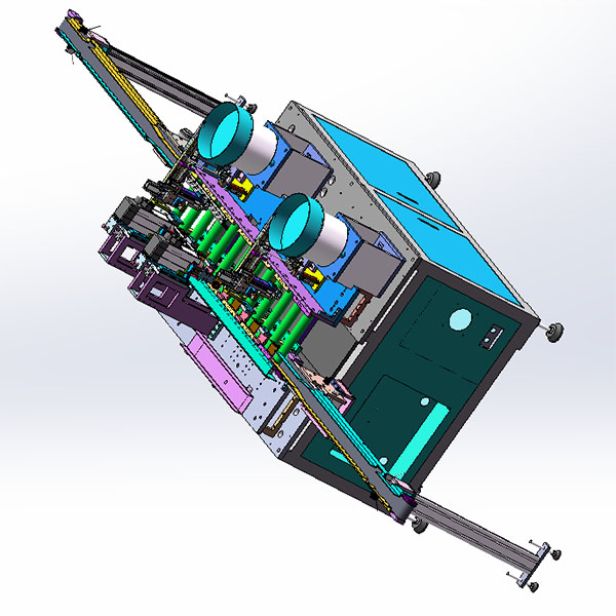

2. Machine Workstation

2.1 Manual Load Unfinished Door Seal From Stack Rack One by One With Machine Running;

● Operator Pick up unfinished door seal from seal stack rack one by one and insert door seal to machine;

● At the another end of feeding track for door seal, there is stop mechanism to stop door seal, and an in-position sensor mounted on the stop mechanism detect that one end of door seal arrive the expected position;

2.2 Automatic Centering, Cylinder Driven-Hold System Door Seal When Sensor Detect Door Seal Arrive At Expected Position;

● After door seal pushed and arrived at expected position and an in-position sensor detected, pneumatic cylinder driven centering and hold system will center and hold door seal and ready for drilling;

2.3 One or Two Drilling System Driven By Stepper/Servo Motor To Drill One Or Two Holes

● After door seal centered and hold, one or two drilling system will work to drill holes to

expected depth for door seal ;

● The up and down movement for drilling system that driven system stepper or servo motor with ball screw system to control the drilling up and down speed to reduce the damage from drilling system due to improper pressing force;

● When the drilling system is working, an air-blowing system will work together with drilling system to blow off scraps as the first clean step.

2.4 After Drilling Process, Door Seal Transferring System Move To Pin Insertion Workstation

At Opposite Side. ● After one or two holes are processed by drilling system, the door seal hold system will work to raise the door seal and transfer from drilling system side to pin insertion system side;

● During door seal transferring, a brush sweeping system to sweep scraps as second clean step;

2.5 Automatic Pin Load, Feed, Sequence, Separate & Hold Pins And Ready For Pin Insertion;

● Full-custom vibratory feeder bowl is introduced to load, orientate, sequence and feed pins;

● Bottom linear vibration driver will be introduced to driven pin feeding track( lane) to transfer the sequenced pins to move forward in line;

● At the end of feeding track, a separating mechanism is designed and engineered to separate 1 pin into single work piece from end of feeding track;

● One In-position Sensors is mounted on the separating mechanism to detect if pin moves to the exact separate mechanism and then provide a signal to require PLC to enable the separating mechanism to separate pins into work piece;

● Pneumatic finger cylinder will hold the separated single pin and move with the pin insertion system from current position to insertion position;

2.6 One Or Two Pin Insertion Mechanisms Located in Different Location To Insert One Or Two Pin Insert The Drilled Holes;

● Pin hold & insert system consists of automatic transfer system to hold separated pin, move up and forward, move down and insert pin into holes of door seal by one or two pieces at the same time.

● A pneumatic cylinder driven pin insertion system with spring compression force reducing

system to insert the hold pin slowly and to ensure pin can be inserted at exacted position;

2.7 Manual Remove The Finished Door Seals And Place Them Into Final Product Rack;

● After one or two pins are inserted into door seals, it requires the operator to remove the

finished product from machine and place them onto finished product racks. Remarks:

Due to different size of door seals, it requires operator to adjust the distance of drilling systems and pin insertion system in accordance the actual distance of two holes onto door seals.

3. Technical Parameters

3.1 Dimension & Gross Weight

Overall Dimension: Approx. 1200×1200×1850 mm

Gross Weight: Approx.400kg

3.2.Machine Parameters

Production Rate: 10-15 /min. Operator Number: 1 operator required to operate this process machine;

Power Supply: 220V.50Hz,Single Phase

Air Supply: Above 5.0kgf/cm²