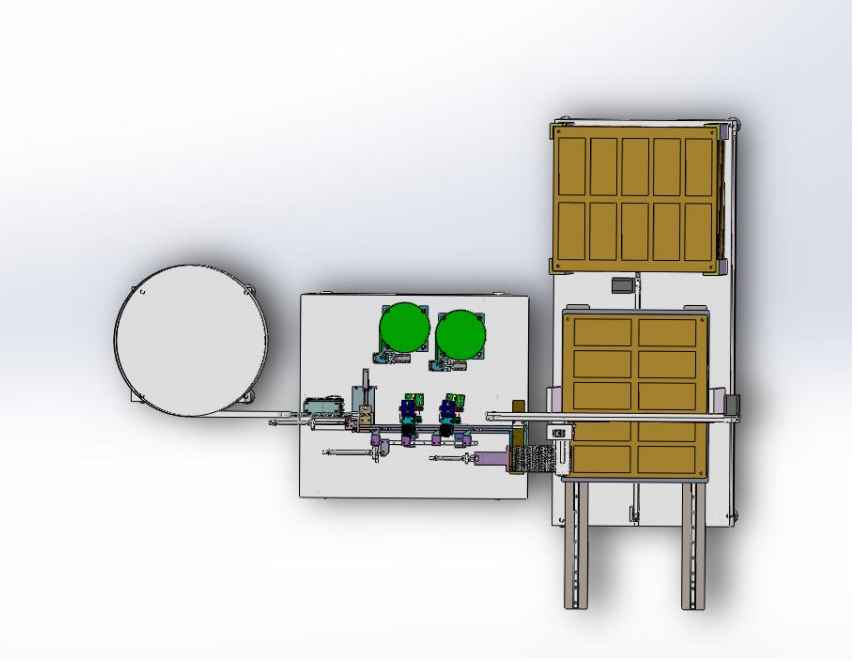

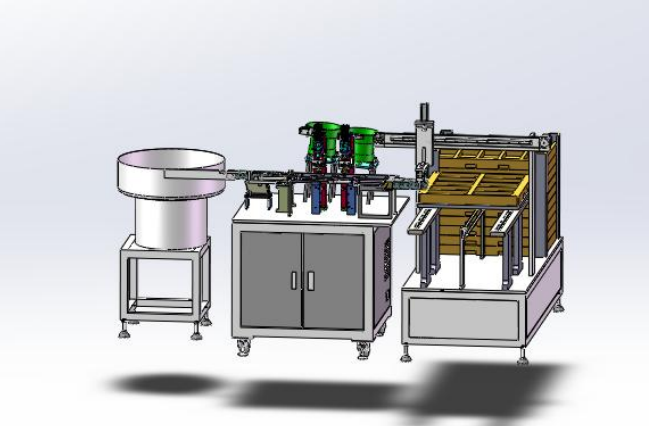

Machine Overview

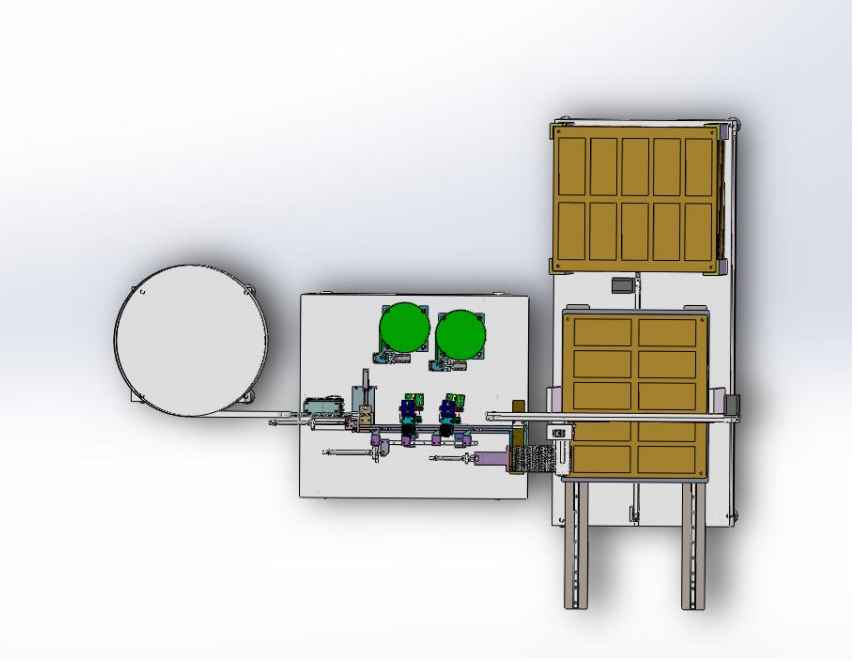

3.2 Machine Workstation

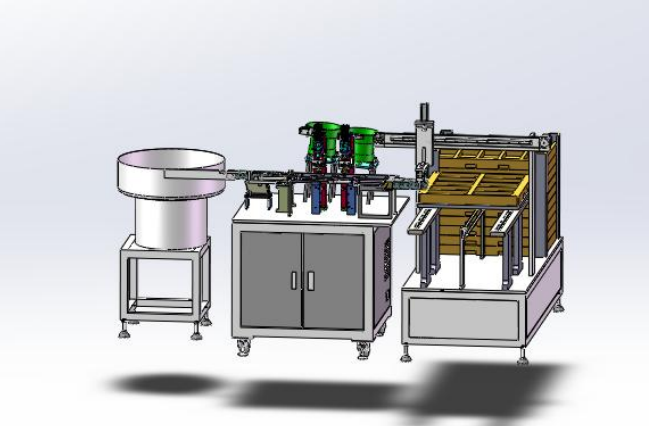

3.2.1 Plastic Housing Load, Feed, Orientate, Sequence, Separate & Push-Into Assembly Track

● Full-custom vibratory feeder bowl is introduced to load, orientate, sequence and feed plastic housing;

● Plastic Housing Feeding Tracks (Lanes) driven by linear vibratory feeder to transfer plastic

housing to move forward in line;

● At the end of feeding track, a separating mechanism is designed and engineered to separate plastic housing into single work piece from end of feeding track;

● In-position Sensors are mounted on the separating mechanism to detect if plastic housing move to the exact separate mechanism and then provide a signal to require PLC to able the separating mechanism to separate plastic housing.

3.2.2 Screw1 Feed, Orientate, Sequence, Separate & Air-Blow Into Screw Drive Mechanism 1

● Vibratory feeder bowls will be introduced to load, feed, orientate, sequence screws;

● Sequenced screws 1 will be transferred by transportation track(lane) that driven by bottom linear vibration driver till to screw1 in-position detection and separating mechanism;

● At the separating mechanism, an in-position sensor is mounted to detect if screw 1 come

from feeding track in position. Once one screw entered into separate mechanism and in-position,separating mechanism driven by pneumatic cylinder will work to separate screw into single work piece and ready for air-blow into screw drive mechanism 1;

3.2.3 Servo Motor With Torque Control To Drive Screw To Screw Hold 1 of Plastic Housing

● Screw drive system that driven by servo motor with excellent screw drive torque control will be introduced to implement screw drive process;

Remarks: To introduce servo motor for screw drive system can ensure the assembly system to achieve the benefits such as:

a. Screw drive speed controllable;

b. Available to detect screw missing, screw thread slip etc;

c. Signal feedback to PLC control system to Sort NG products from OK product;

● Single servo motor screw drive workstation with torque control to drive screw one by one to assemble screws and plastic housing and the PLC will gather the screw drive data to provide a single to determine if any failure of screw drive.

3.2.4 Screw 2 Load,Feed, Orientate, Sequence, Separate air-blow into screw drive mechanism

● Vibratory feeder bowl is also taken the popular and stable loading and feeding system to load, feed, sequence and orientate screws 2;

● Linear vibration driver is installed above screw feeding track to transfer sequenced screws 2 to in-position detection and separating mechanism;

● At end of screw feeding tracks, a screw detection mechanism with fiber sensors to detect if screw 2 entered into separating mechanism. And then if screw detected in position, the

separating mechanism will air blow screw 2 into screw 2 drive mechanism.

3.2.5 Servo Motor With Torque Control To Drive Screw To Assemble Terminal with Yokes

● Screw drive system that driven by servo motor with excellent screw drive torque control will be introduced to implement screw drive process;

Remarks: To introduce servo motor for screw drive system can ensure the assembly system toachieve the benefits such as:

d. Screw drive speed controllable;

e. Available to detect screw missing, screw thread slip etc;

f. Signal feedback to PLC control system to Sort NG products from OK product;

● Single servo motor screw drive workstation with torque control to drive screw one by one to assemble terminals and yoke clamps and the PLC will gather the screw drive data to provide a single to determine if any failure of screw drive.

3.2.6 plastic housing Push-Walk Mechanism

● A push-walk mechanism driven by pneumatic cylinders with forks to push plastic housing

forward one step by one step from one station to another station;

● Push-walk mechanism will provide a flexible movement control for plastic housing forward from one workstation to another, thus allow the screws be assembled with plastic housing one by one and also enable the screw drive process one by one;

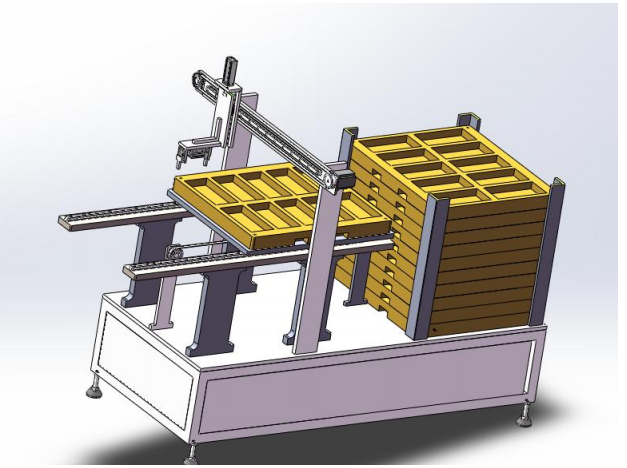

3.2.7 Final NG Sort & Final OK Unloading

Final NG sorting mechanism will differ the NG Product from OK product on basis of signal

transferred from servo motor screw drive system with torque control. NG products as below will be Sorted:

Screw missing;

Screw missing will cause empty load and zero torque for servo motor;

a. Screw thread damage;

Screw thread damage will cause servo motor overload and screw get stuck during screw drive;

b. Failures of screw driven etc. Other failures such as wrong depth of screws etc. Remarks: by this single servo motor screw drive system to ensure each single screw are driven

into plastic housing with setup torque and ensure there is no damage of screw or terminal. ● Final OK product will directly sequenced by 10 pcs/row

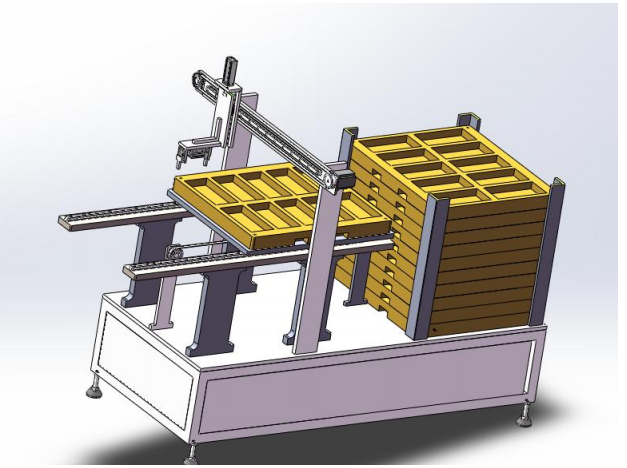

3.2.8 Manual Pick Stacked Tray and Put Onto Tray Holder;

Operator will pick up empty tray from stacked trays and place it onto tray holder platform;

3.2.9 Stepper Motor Drive X-Y Robot Pick And Place Sequenced Plastic Housing & Place into Cavities of Tray ;