General Introduction

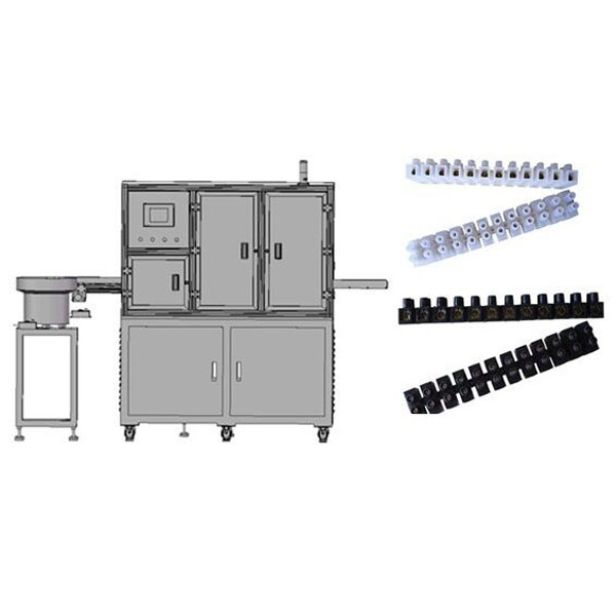

Automated Strip Connector Assembly Machine with excellent performance that enables connector and terminal block manufacturer worldwide to achieve one-stop assembly automation solution to automate their current production line.

From Automatic Loading, Feeding, Separating to current terminal insertion, screw press-into, screw-drive to final checking and inspection, this automated strip connector assembly machine allows manufacturers to get high

productivity and high quality final connector products.

Introduced with excellent ball-screw and servo motor drive system, this automated strip connector assembly machine with versatility to be used for many types of connectors with same size which are only designed with different terminal

quantity inside of strip connectors.

Machine Features

According to assemblability principle, all parts and components introduced with fully customized feeding system to realized automatic sequencing, orientation, conveying, identification and separating.

Servo Motor or Pneumatic Cylinder Drive System assists plastic housing moving stable on assembling tracks, convenient for processes alike brass terminal push-into, screw press in, screw drive ..etc.

Servo Screwing System with Advantage of free setting screwing torque force as well as to determine failures such as screw off position, wrong position, slippage to guarantee the final product quality from customer end.