General Introduction

1.Pallet Chain Driven Conveyor

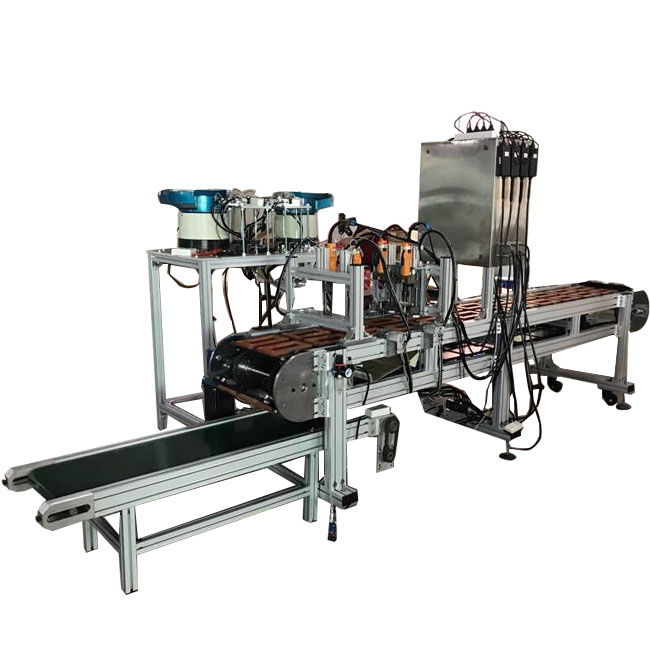

■ Automated Screwing Machine will be designed to be driven by stepper motor, pallet chain conveyor and carrier onto pallet configuration, and in-line automation

layout type.

■ Bear Roller Will Be introduced As the wheel that mounted for pallet that carry the pallet to move forward thus to reduce the impact to stepper motor and gear box,

which will ensure machine run in stable performance.

2.Screw Drivers

■ 4 Electric Screw Drivers Are Mounted onto The End of Pallet Chain Drive Conveyor; Screw Drive Driven By Electric Driven Method;

■ To Center and Hold Power Socket During Screw Drive, A Pressing-Hold Mechanism Will Be introduced to Press Down when screw drive descend to hold products

in case of product movement;

■ 4 Electric Drivers must be controlled by PLC system independently and must be adjustable to adjust up and down, left and right, forward and backward and also

height for different products

3.Carriers

■ The Carriers must be designed to allow two pieces of larger-size power sockets and make two of them side by side placement, while for smaller size of power

socket, 4 pieces can be placed into carriers;

■ After manual pre-assembly of power socket base and cover, the power sockets are placed into carriers manually and without any clamping and holding

mechanism;

■ After Screw Drive Performance, the power sockets will be unloaded by falling down and dropping into final product container when the pallet that carry

carriers move to the end of Chain driver conveyor and rotates.

4.Carriers Changeover

■ A Bottom Plates with bearing roller are designed with Pin Holes Provide an easy access for carriers changeover in short interval and quick positioning and

centering;

■ The top carriers is made of POM or bakelite material and keep a tolerance less than or equal to 0. 5mm and pin holes are made to match with pin that mounted

for bottom plate thus to ensure a quick changeover of carriers.

5.Detection & Control

■ 4 Fiber Sensors are mounted to detect two large-size of power sockets or 4 small-size of power sockets to sense and detect products;

■ Each Fiber Sensor For Each Power Socket;

■ It requires that any missing for power socket, once fiber sensors fail to detect product, relevant electric driver won't implement screw drive for relevant position.

6.Screw Feeding & Separating

■ Screw Loading & Feeding is introduced with vibratory feeder bowl and two feeding tracks are designed for vibratory feeder bowl;

■ At the end of feeding tracks for each vibratory feeder bowls, independent screw separating mechanism are designed and mounted to separate screw for screw

drivers;

Air blowing method to push the separated screw into nose of screw driver.

Main Features

1) Simple structure in linear type ,easy in installation and maintation.

2) Adopting advanced world famous brand components in pneumatic parts ,electric parts and operation parts.

3) High pressure double crank to control the die opening and closing.

4) Running in a high automatization and intellectualization,no pollution

5) Apply a linker to connect with the air conveyor ,which can directly inline with filling machine .